our quality qc + qa program

Quality

Our global customer base is growing and loyal to George Stevens for several reasons, one of which is our commitment to ensuring the quality of delivery of durable and high-performing products to optimize your winding productivity.

World-Renowned

Equipment

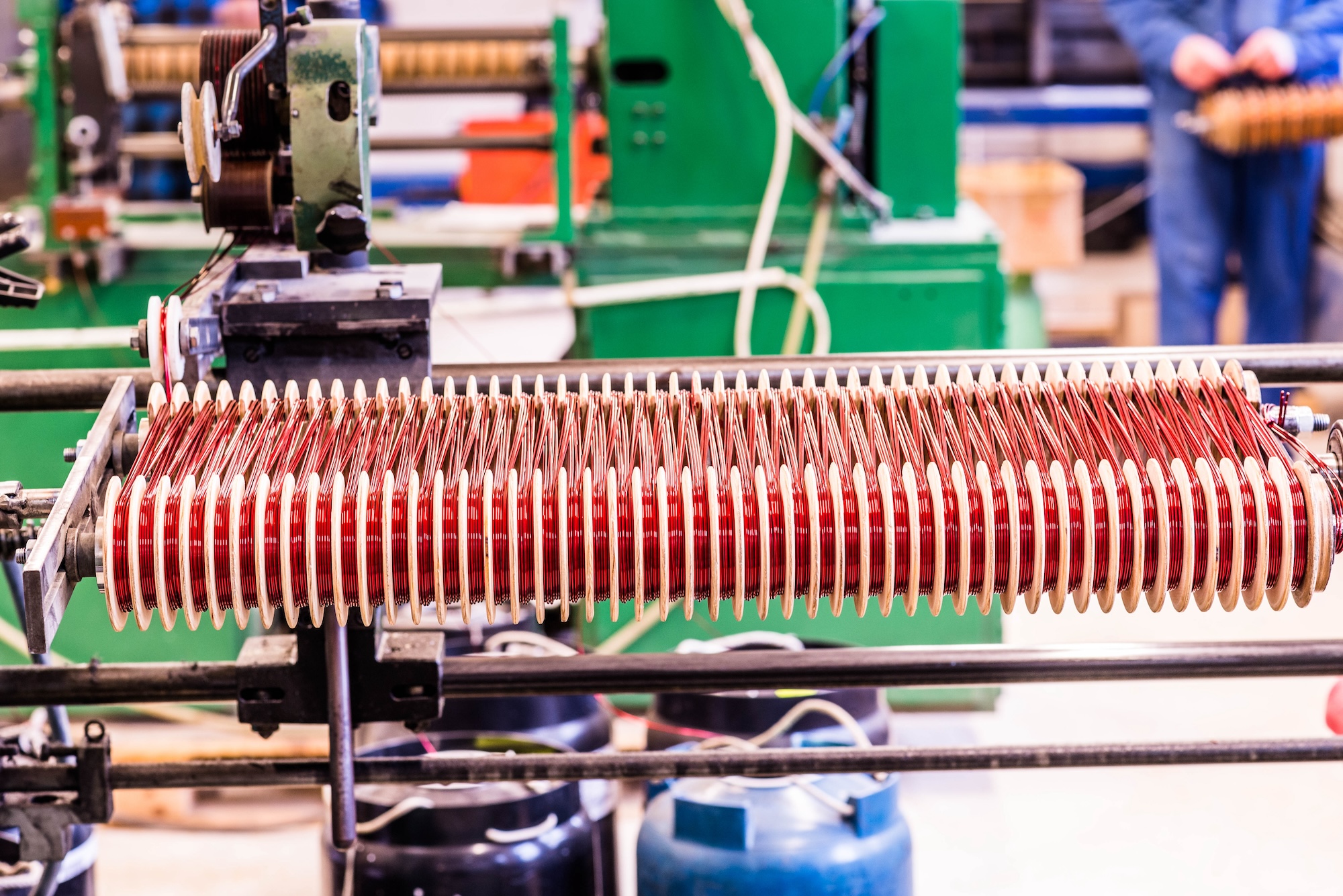

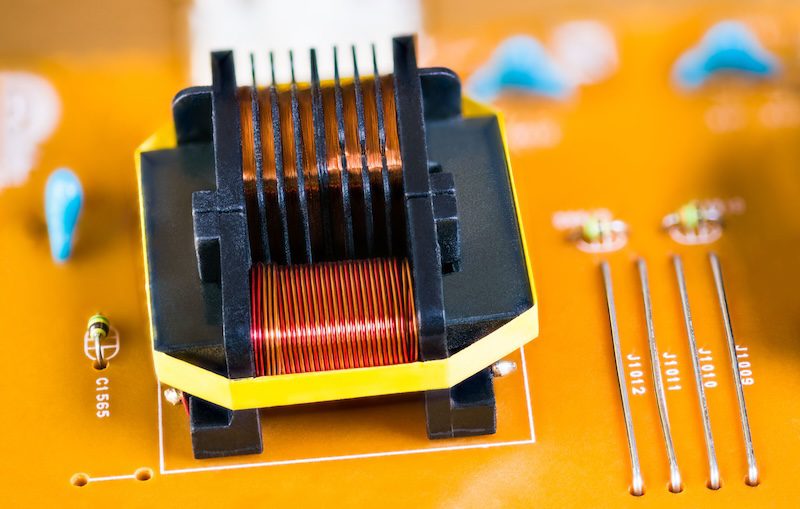

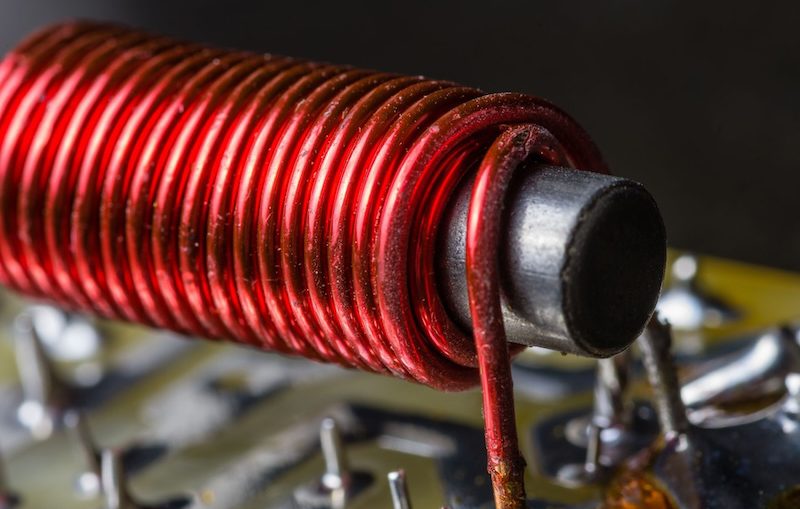

Matching design with your production needs, our range of transformer winding machines and coil winding equipment is ideal for normal production and small, medium, and large applications. We are your best choice.

From standard production to customer design, we manufacture to optimize your winding needs

From our comprehensive line of standard equipment to options customized for your specific needs, our goal is to provide a solution that will server you in the long term and make your production more efficient and profitable.

a global perspective

Markets

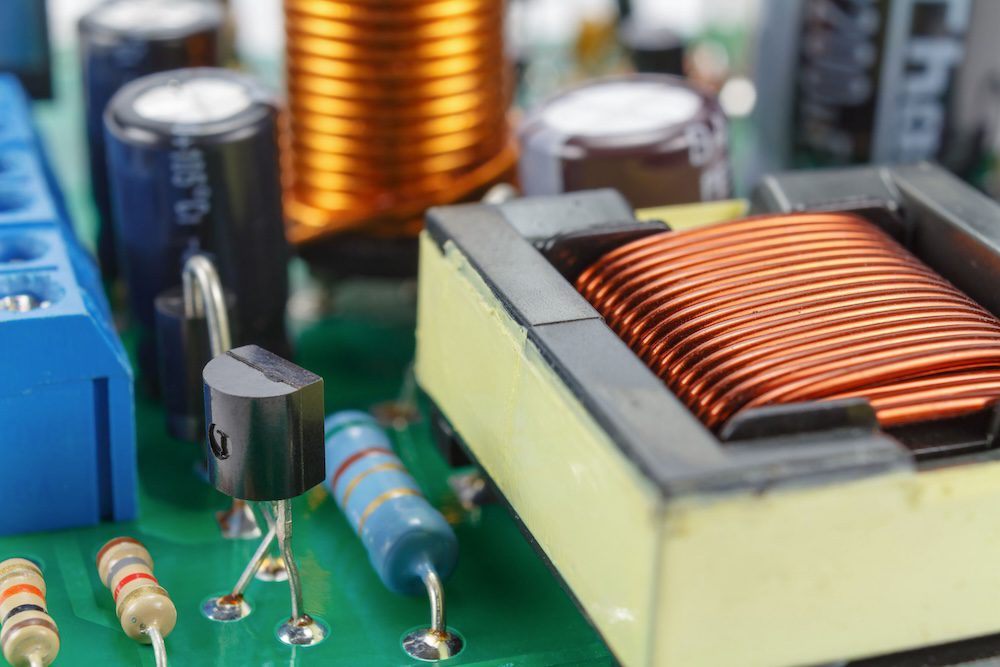

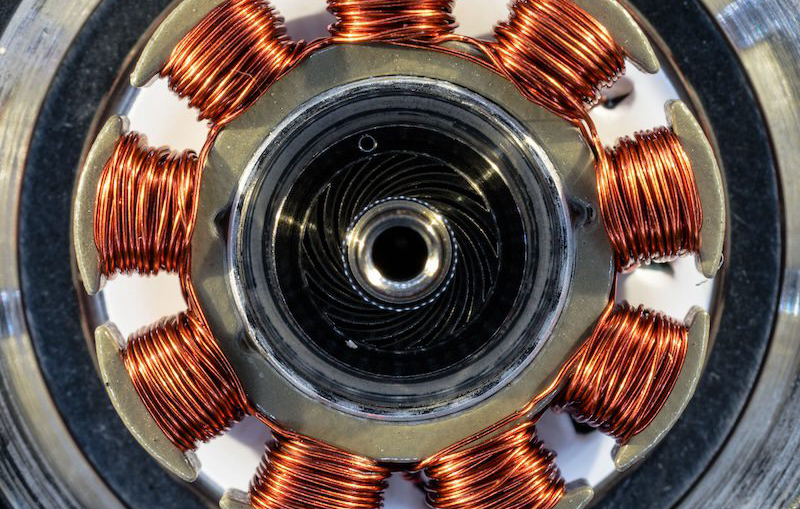

George Stevens is truly an innovator in developing coil winding solutions for a wide variety of industries and applications. Our systems are currently used in small to large scale productions as well as R&D Applications. Our industry impact is Global and widely applied to products such as but not limited to:

- Power Distribution and Control Instruments

- Automotive Products

- Military Equipment

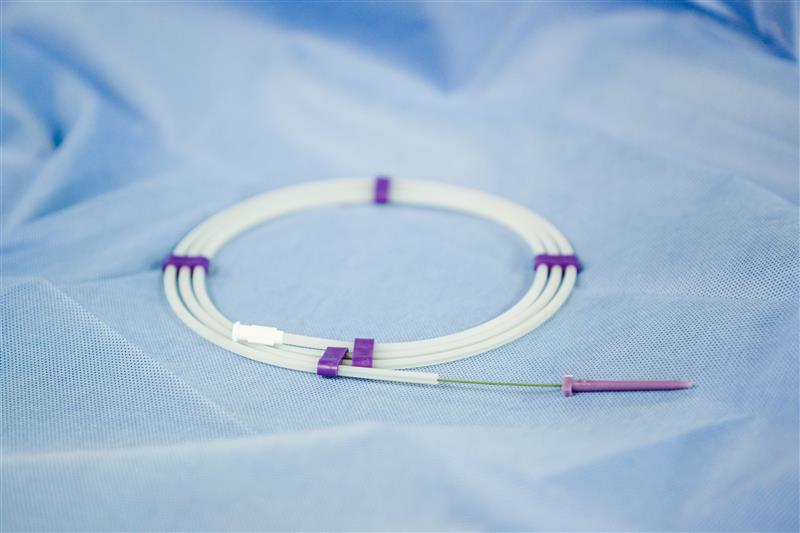

- Medical Instruments

- Music Industry

- General Industrial and Consumer Electronics

Medical products (Cardiovascular)

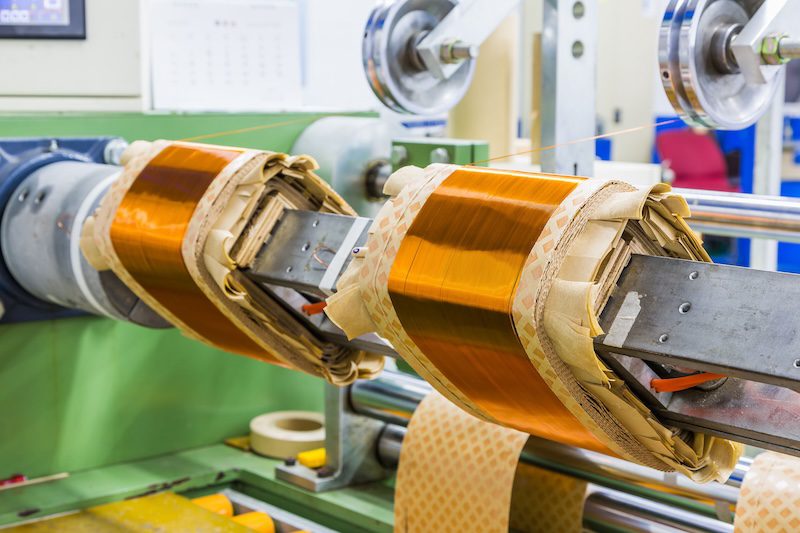

Distribution transformers

Hearing aids

high and low voltage power supplies

electric motors and more

precision and reliability

Manufacturing

Using resources for precision and reliability, we count people as our best resource. Our professionals are skilled craftsman who apply their knowledge of modern-day engineering to build machines that last and reform.

- Majority of our mechanical parts are machined and fabricated in our fully equipped machine shop.

- In addition to our off-the-shelf equipment, we also offer customized solutions.

- Our time frame for design and production always fits your schedule.

- Our design uses the latest in SolidWorks innovations for precision and reliability.

- Our factory staff is trained in the latest technology and safety practices.

developed for efficiency

Software & Control

smc-1

A coil-winding machine controller contains a step motor drive, motor speed control, electrical gearing capacity, brake power supply, and an easy-to-read interface in one fully integrated enclosure.

smc-2

A hand-guided coil winding machine controller contains motor speed control, brake power supply, and an easy-to-read interface in one fully integrated enclosure.

We are also capable of creating a customized control system to match specific needs.